Spradling produces both standard and custom flame-laminated products using advanced technology and strict quality standards (ISO 9001-2015 certified). Materials include vinyl, textiles, plastics, and flame barriers bonded to foam and fabrics (meeting Docket 90 for transportation and theatre seating). Custom orders are welcome.

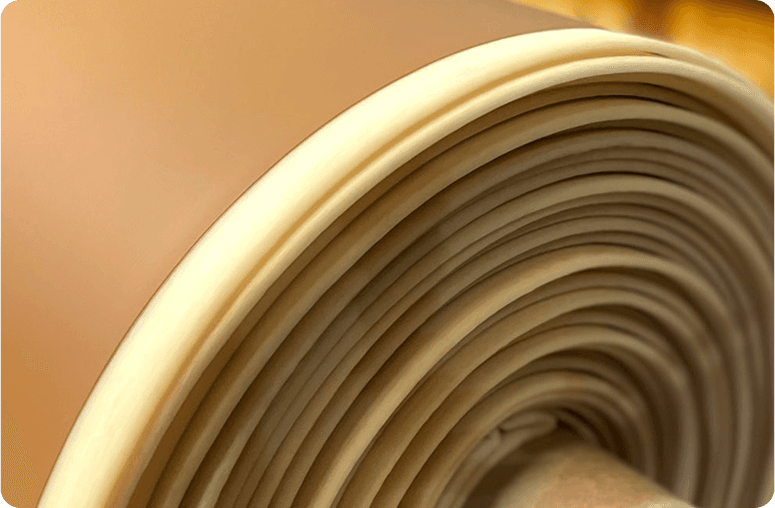

Flame lamination bonds two materials by briefly exposing foam to a flame. The heat melts the foam surface, turning it into an adhesive. A second material is pressed onto it, creating a strong bond.